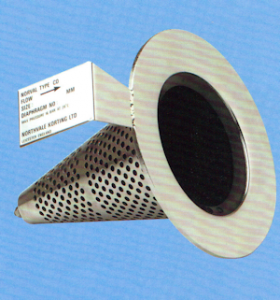

Check or Flow Control Valves

Witches Hat Valves

Witches Hat Valves

A little valve with the big difference!

Many pipeline systems need some type of check valve device to keep flow in one direction. Check or flow control valves may be needed to either prevent contamination of liquids that are already in the system or stop damage to pipework and components. Whilst this sounds quite a simple requirement, the reality is that it needs a specialist solution.

What features does a piping engineer need in check or flow control valves?

- • Complete closure under minimum back pressure

- • There must be a rapid response to either no-flow or reverse flow conditions

- • Low resistance to forward flow

- • Light weight construction

- • Easy installation for unskilled operators

- • No Maintenance

The Norval Non-Return Check Valve has these features and a few others

- • Simple design

- • Can operate in any direction, be it vertically up or down, or horizontally

- • High specification 316 stainless steel material

- • Low noise signature when closing – no “slamming shut” during a reverse flow

- • Can be configured in a wide variety of ways or built into existing equipment as a cone and diaphragm assembly

How the Norval Non-Return Check Valve Works

When the flow is in a forward direction the diaphragm is forced inwards (A) to allow liquid to flow with minimal loss of pressure. |

|

| When there is no flow, or back pressure the diaphragm seals off all flow in the reverse direction (B) .The Norval Non Return Check Valve operates effectively in either the vertical or horizontal orientation action is unaffected by the orientation of the Norval Non Return Check Valve. | Stop Silent is a registered trademark of Northvale Korting. |

Click Here to download our “Witches Hat” Check or flow control valves brochure

View our booklet by clicking on the image below